Heritage site gets YR’s Fosroc Treatment

The Torpedo Bay Navy Museum which opened in 2010 is an exhibition like no other. Situated at the base of North Head on Auckland’s North Shore the museum covers a period of naval history commencing with the Flagstaff War in 1845. It encompasses two world wars and has displays on the RNZN’s role in the Korean, Vietnam and Gulf Wars as well as the most recent conflict in Afghanistan.

The Torpedo Bay location has a colourful history. Many of the buildings on the present site date back to the nineteenth century when in response to the threat of a Russian Invasion scare they were used as a Mine Store to help with Auckland’s defence against the foreign invaders. It was later to become an ammunition store.

The Mine Store, is a New Zealand historic building of national significance and is made of unreinforced masonry with the walls being approximately 400mm thick. With the help of Youngman Richardson the Mine Store is being restored and repurposed in the form of two gallery areas and a new learning space. This is all being done to bring the past back to life for future generations to enjoy.

The company given responsibility for the restoration was Legacy Construction who are well known for their large scale refurbishments and structural repair work in historical buildings. The company has built its reputation on high quality workmanship and cost effective solutions which are second to none.

Prior to commencing the project Youngman Richardson was called in to evaluate what products would be required to assist with the restoration. Initially it was for the Mine Store walls but as time progressed Youngman Richardson extended their involvement into more of the project. The unavailability and impractical nature of some of the specified products together with Youngman Richardson’s expertise in providing sensible solutions meant that their contribution was extended beyond what was originally planned.

“The architects specifications for the cracks in the Mine Store walls called for a Fosroc injection repair system,” says Legacy Construction Site Manager, Mike Dines. “Initially we weren’t sure whether anyone locally could supply the Fosroc product. However after undergoing some research we found that Youngman Richardson were not only the local suppler of the product but also very knowledgeable about its applications,” says Mike Dines.

Fosroc has a comprehensive range of above and below the ground waterproofing products and systems such as repair mortars, corrosion management, protective coatings and strengthening systems. “Across this project we went with a range of Fosroc repair materials including Conbextra EP10 for crack repair, Renderoc FC for Detailing Render, Hydrotite DSS0220 for construction joint waterproofing, and Vandex Plug for water-stop repair,” says Mike.

An issue that came up while talking to Youngman Richardson was the plaster restoration of the walls. An opposition product had been specified for this job but there was a supply delay and with time running out Legacy Construction once again turned to Youngman Richardson for advice. This came in the form of another product from Fosroc which proved the equal of the original specification if not better.

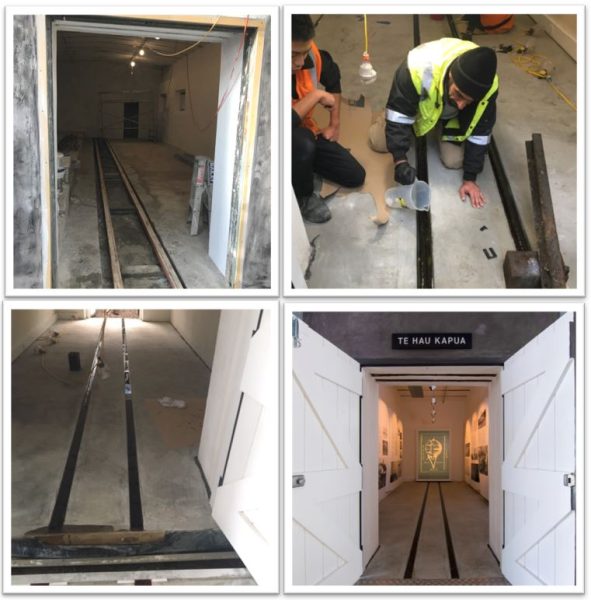

When the building was used as a mine store there were railway tracks installed to transport ammunition between the 3 stores. Whilst the tracks no longer had any functional value they did provide a design element for the new galleries and learning space. The tracks were initially removed and cleaned. New floor slabs were then put in, waterproofed and new drainage installed. A rebate was then formed in the slab for the tracks to sit in. The tracks were reinstalled and a clear casting resin supplied by Youngman Richardson was applied to protect the tracks. In this instance the original specification was for the tracks to be covered with a darker resin which meant the tracks would effectively be hidden from view. Youngman Richardson were able to provide the solution and ensure that the tracks remained visible.

“Youngman Richardson were great to work with particularly their Fosroc specialist Dana Stiles with his wealth of experience and knowledge. He also went out of his way to personally deliver product to the site at a moment’s notice,” says Mike Dines.